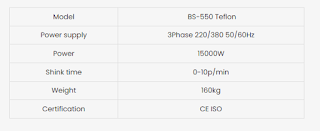

The BS-550 Teflon Heat Shrink Machine is a professional packaging device designed to apply heat to shrink film tightly around products, providing enhanced protection and visual appeal.

Product Description

Advantages

- Rapid Heating System

- Features a fast and efficient heating system that evenly distributes heat to ensure tight and secure shrink wrapping.

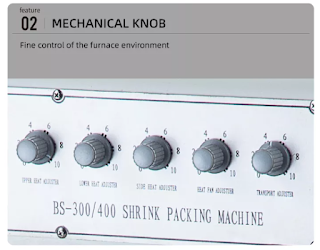

- Adjustable Settings

- Easily adjustable temperature and speed settings allow for versatile use with various shrink films and product sizes.

- Compact Design

- Its space-saving design makes it suitable for businesses with limited floor space while maintaining high packaging performance.

- Simple Operation

- The user-friendly control panel enables quick setup and operation, reducing training time for staff and improving productivity.

Description

The Heat Shrink Machine is a reliable and efficient solution for securely packaging products using heat-sensitive shrink films. Designed to deliver fast and uniform results, it provides durable packaging that protects products from dust, moisture, and damage. Its compact design and easy operation make it a perfect choice for businesses looking to enhance packaging efficiency without occupying excessive space.

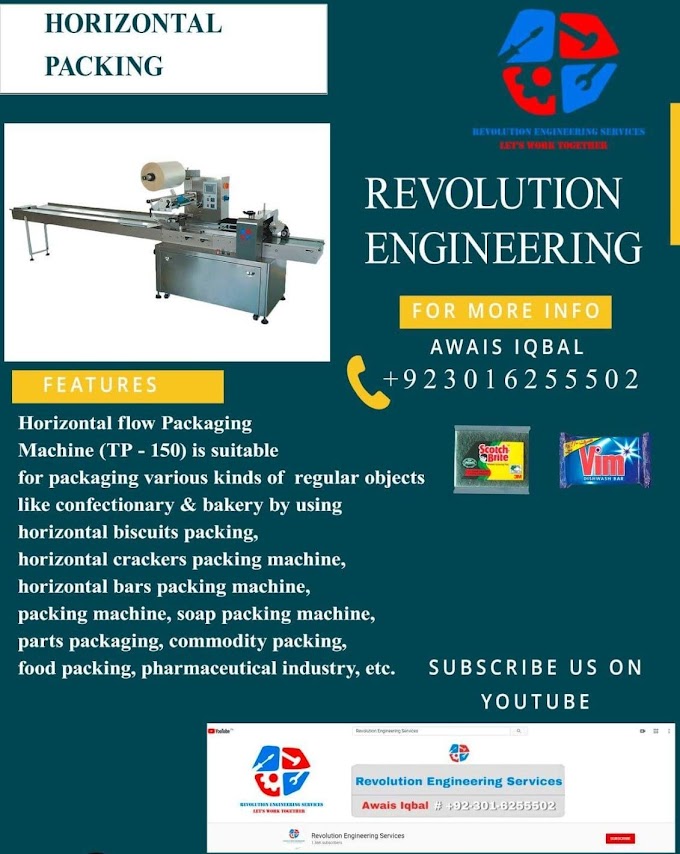

Applications

The Heat Shrink Machine is ideal for:

- Food Packaging: Wrapping items like snacks, frozen food, and fresh produce for extended shelf life and better protection.

- Electronics: Packaging small devices and components to protect them during transport and storage.

- Retail Products: Shrinking films around consumer goods for an attractive, tamper-proof presentation.

- Industrial Parts: Safeguarding tools and mechanical parts with durable, dust-proof packaging.

Advantages

- High Efficiency

- The machine operates at high speed, reducing the time needed for manual packaging and boosting overall productivity.

- Durable Packaging

- Produces strong, tamper-resistant wraps that protect products from external factors like dirt and moisture.

- Versatility

- Handles a variety of product shapes and sizes, making it adaptable to different industries and packaging needs.

- Energy Saving

- Designed to consume minimal power while delivering consistent results, lowering operational costs.

- Low Maintenance

- Made with durable components, the machine requires minimal maintenance, ensuring long-term, trouble-free use.

- Improved Presentation

- Provides a smooth and professional finish, enhancing the product's appearance and marketability.

0 Comments