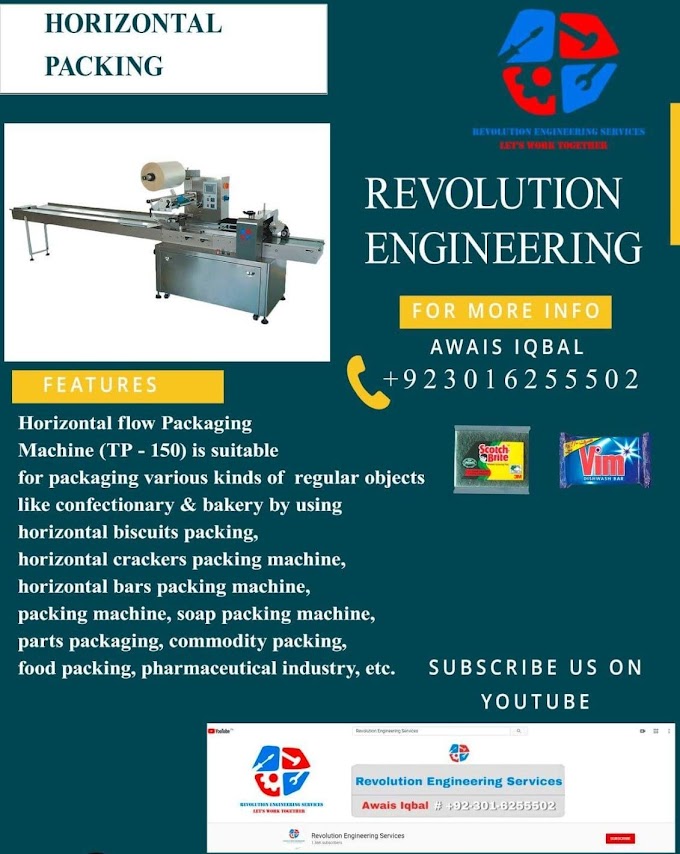

The Horizontal Packing Machine, also known as a Pillow Wrap Packing Machine, is a highly efficient packaging solution designed for packing items into a pillow-shaped wrap. This machine is widely used in various industries, such as food, pharmaceuticals, and consumer goods, due to its versatility, speed, and precision. Whether you’re packaging biscuits, chocolates, soaps, or medical supplies, this machine ensures a professional finish with airtight sealing.

Specifications of Horizontal Packing Machine:

1. Packaging Type: Pillow-shaped packs

2. Material Compatibility: Plastic film, aluminum foil, laminated film, or paper-based wraps

3. Speed: 30-300 packs per minute (adjustable based on product size and material)

4. Power Supply: 220V/50Hz (customizable based on region)

5. Product Size Range: Adjustable for length, width, and height

6. Sealing Mechanism: Heat sealing (adjustable temperature for different materials)

7. Control System: PLC with touch-screen interface for easy operation

8. Material of Construction: Stainless steel for durability and hygiene

9.Machine Dimensions: Compact design for space-saving installation01

10. Warranty: 1-2 years

Features of Horizontal Packing Machine:

1. Versatile Applications

Can handle a wide range of products, from solid items like biscuits and chocolates to non-food items like soaps and hardware.

2. High-Speed Operations

Ensures rapid packaging for mass production without compromising on quality.

3. Adjustable Settings

Easily adjustable for various product sizes and packaging materials.

4. Compact Design

Space-efficient, making it suitable for small-scale businesses or large production lines.

5. User-Friendly Interface

Equipped with a touch-screen control panel, allowing for smooth and intuitive operation.

6. Airtight Sealing

Ensures products remain fresh and protected from contamination.

7. Low Maintenance

Durable design requires minimal maintenance, reducing downtime.

Usage of Horizontal Packing Machine:

1. Food Industry:

Products: Biscuits, cakes, chocolates, candies, bread, or snacks.

Purpose: Keeps food fresh, hygienic, and visually appealing.

2. Pharmaceutical Industry:

Products: Medical supplies, bandages, or tablets.

Purpose: Protects from moisture and contamination, ensuring safe delivery.

3. Consumer Goods:

Products: Soaps, toothbrushes, small toys, or electronics.

Purpose: Secure packaging that enhances product presentation.

4. Industrial Goods:

Products: Small tools, screws, or machine parts.

Purpose: Protects items during transportation and storage.

---

Benefits of Horizontal Packing Machines:

1. Professional Packaging

Provides a consistent, polished look that enhances brand value.

2. Cost-Effective

Reduces labor costs and packaging waste, improving overall profitability.

3. Versatile Applications

Suitable for multiple industries, offering flexibility in product packaging.

4. Time-Saving

High-speed operation increases production efficiency.

5. Hygiene Assurance

Ensures products are securely packed, maintaining cleanliness and freshness.

---

Business Opportunities with Low Investment:

Investing in a Horizontal Packing Machine opens doors to numerous business possibilities. Here are a few examples:

1. Snacks Packaging Business

Products: Biscuits, cakes, or candies.

Investment: Low to moderate.

Profit Potential: High, with consistent demand for packaged snacks.

2. Personal Care Products Packaging

Products: Soaps, toothbrushes, or small cosmetic items.

Investment: Low.

Profit Potential: Moderate, with increasing consumer focus on hygiene.

3. Pharmaceutical Supplies

Products: Bandages, syringes, or tablets.

Investment: Moderate.

Profit Potential: High, due to the demand for hygienic medical supplies.

4. Custom Packaging Services

Offer packaging solutions to small manufacturers and retailers who lack the infrastructure to package their products.

---

Advantages of Horizontal Packing Machines:

1. Compact and Space-Saving

Suitable for businesses with limited space.

2. Low Maintenance Costs

Built for durability, ensuring long-term use with minimal servicing.

3. Eco-Friendly Options

Compatible with recyclable and biodegradable materials.

4. Enhanced Product Protection

Prevents damage during storage and transportation.

---

Scope and Market Potential:

The demand for professional packaging is growing across industries. From small startups to large-scale industries, everyone needs secure, attractive, and cost-effective packaging solutions. With a Horizontal Packing Machine, you can tap into a wide range of markets, including local vendors, export-oriented businesses, and e-commerce sellers.

Starting a business with this machine not only ensures a steady income but also allows entrepreneurs to expand their services as their customer base grows.

---

Conclusion:

The Horizontal Packing Machine (Pillow Wrap Packing) is a versatile, efficient, and cost-effective solution for businesses seeking to improve their packaging processes. Whether you are starting a new venture or upgrading your existing operations, this machine can help you achieve professional results with minimal investment.

At Revolution Engineering Services, we provide high-quality Horizontal Packing Machines tailored to meet your business needs. Contact us today to explore your options and take the first step toward revolutionizing your packaging process!

0 Comments